E-mail: admin@saifutd.com Tel: 86-13598853789

E-mail: admin@saifutd.com Tel: 86-13598853789

news

The coal mined in coal mining usually contains some impurities, and the separation efficiency of coal and impurities can be improved by adding flotation agents. The clean coal is flotation and the tailing coal is settled. The clean coal in the tailings is then recovered by settling, filtering or centrifuging. Polyacrylamide is used in the sedimentation process to promote solid-liquid separation. Then it is sent to the thickener, and the clear water is recovered from the overflow of the thickener and recycled. Powdered clean coal is recovered by filtration and centrifugation. Adding polyacrylamide again during filtration and centrifugation improves separation efficiency.

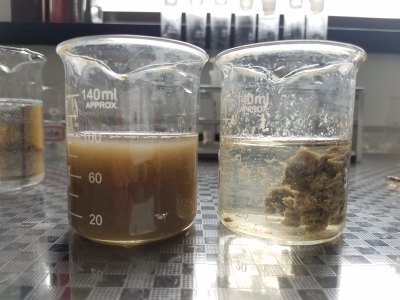

Coal-washed polyacrylamide is a more specialized polyacrylamide. In fact, only the internal chemical composition content has been adjusted. The special polyacrylamide for coal washing is several times more effective than ordinary polyacrylamide. It is very effective in coal washing press filtration, or in the discharged groundwater. Its reaction time is about 5 seconds and you can see the effect of precipitation. , So many coal mines choose the special flocculant for coal washing.

Anionic polyacrylamide for coal washing, also known as special agent for coal washing. The molecular weight is 8 million to 18 million. Polyacrylamide for coal washing In order to make the slime water settle quickly in the thickening tank, ensure the production of qualified coal washing water and press filter coal slime, and make the production run efficiently and economically, it is necessary to select a suitable flocculant to strengthen the treatment of the slime water.

Polyacrylamide, referred to as PAM, is a linear high-molecular polymer, non-toxic, non-corrosive, and easily soluble in water. After its aqueous solution is mixed with coal slime water, the active groups on the molecular chain of polyacrylamide for coal washing and Adsorption occurs on the surface of the fine particles in the slime water, which acts as a connection between the particles, making the fine particles form larger flocs and speeding up the sedimentation of the slime. The addition of polyacrylamide aqueous solution specially used for coal washing is a key link in the treatment of coal slime water, and the appropriate addition method will help to improve the flocculation effect.

In the treatment of coal slime sewage, an appropriate amount of coal washing polyacrylamide must be added to effectively exert its flocculation effect. It can be determined through experiments according to the selected slime water treatment process and the properties of the slime water. The dosage is small, the sedimentation speed of coal slime is slow, the concentrated overflow is easy to exceed the standard, the required circulating water index cannot be guaranteed, and the coal washing product index is difficult to control stably.

If the amount is too much, although the sedimentation speed of the coal slime is accelerated, it is easy to cause the concentration of the concentrated underflow to be too high; generally, the concentrated underflow concentration is required to be 500g/L, which can meet the pressure filtration production; if the amount is too large, the concentration of the underflow after concentration may sometimes be It can be as high as 700g/L or more, and the content of polyacrylamide in the underflow increases, which is not conducive to underflow transportation and filter press production. When the filter press unloads briquettes, the briquettes are not easy to fall off, which increases the labor intensity of the operator and reduces work efficiency; the waste of medicines increases the production cost. Therefore, the correct use of polyacrylamide can not only improve the flocculation effect and effectively treat the slime water, but also play an important role in ensuring the product indicators of coal washing, improving work efficiency and reducing costs.

Test instruments and reagents to be prepared for determining the amount of coal washing agent polyacrylamide: turbidity meter, pH meter; polyacrylamide; sodium hydroxide; basic aluminum chloride; beaker; various graduated straws.

Breeding wastewater treatment process

Introduction to slaughtering wastewater and common treatment methods

Introduction to papermaking wastewater and common treatment methodsCharacteristics of papermaking wastewater:Papermaking wastewater is very harmful, among which black water is the most harmful. The pollutants it contains account for more than 90% of the total pollution emissions from the papermaking

Introduction to printing and dyeing wastewater and common treatment methodsCharacteristics of printing and dyeing wastewater: Textile printing and dyeing wastewater has the characteristics of large water volume, high content of organic pollutants, high alkalinity, and large changes in water quality.