E-mail: admin@saifutd.com Tel: 86-13598853789

E-mail: admin@saifutd.com Tel: 86-13598853789

news

Source of slaughtering wastewater:

Slaughter wastewater comes from pen cleaning, leaching, slaughtering and other factory workshops such as cleaning, scalding, dissection, non-staple food processing, animal residues, blood and water, etc. Feces remaining in animals and blood produced during slaughter contain high levels of ammonia nitrogen. If not treated, it will seep into the ground or flow into rivers, naturally causing damage to the water that humans depend on for survival. , leading to the growth of cyanobacteria and large-scale death of fish and shrimp in the water.

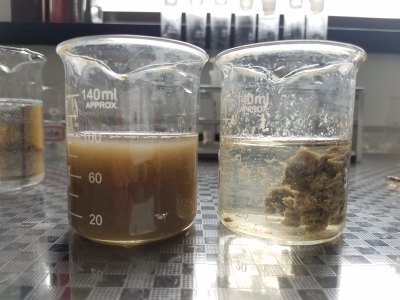

Characteristics of slaughtering wastewater:

It can be seen from the source of the water quality that the wastewater mainly contains blood, grease, minced meat, bone residue, animal hair and feces, etc. The wastewater is brown-red and has a strong fishy smell. It has a high content of organic suspended solids and is easily corruptible. Discharge into water bodies will consume dissolved oxygen in the water, destroy the ecosystem, and pollute the environment. In addition, the biggest difference between it and other high-concentration organic wastewater is its high NH3-N concentration (about 120mg/L). Therefore, the impact of NH3-N on wastewater treatment should be fully considered during process design.

Hazards of slaughtering wastewater:

It has a high content of organic suspended solids and is easily corruptible. Discharge into water bodies will consume dissolved oxygen in the water, destroy the ecosystem, and pollute the environment.

During the slaughtering and meat processing processes, a large amount of water is consumed, and wastewater containing contaminants such as blood, grease, hair, meat scraps, livestock and poultry offal, undigested food, and feces must be removed. This type of wastewater also contains a large number of microorganisms that are harmful to human health. If meat processing wastewater is discharged directly without treatment, it will cause serious pollution to the water environment and endanger the health of humans and animals.

Most of the pollutants contained in meat processing wastewater are easily biodegradable organic matter. After they are discharged into the water body, they will quickly consume the dissolved oxygen in the water, causing fish and aquatic organisms to die due to lack of oxygen. Due to the lack of oxygen, the water body will also transform into an anaerobic state, worsening the water quality, producing odor, and affecting hygiene. At the same time, pathogenic microorganisms in wastewater will multiply in large numbers and harm human health. It is necessary to treat and eliminate the pollution of slaughtering and meat processing wastewater to protect the ecological environment and human health.

Slaughter wastewater treatment process:

1. Grille regulating pool

(1) Mechanical grille: intercept and remove hair and visceral residues in wastewater.

(2) Regulating pool: It stores wastewater and evenly adjusts water quality and quantity, which can effectively slow down the impact of wastewater flow fluctuations and reduce the load.

2. Air flotation coagulation tank

Some low-density grease substances in the wastewater are floated to the liquid surface through air flotation, and then the scum is removed by a slag scraper.

3. Anaerobic pool

In the anaerobic tank, facultative microorganisms are used to reduce the nitrate in the sewage into molecular nitrogen, which escapes into the atmosphere and plays a role in denitrification. The hydrolysis and acidification tank also plays an acidic fermentation role, degrading carbohydrates into fatty acids and converting refractory organisms into Degraded macromolecular substances are converted into easily biodegradable small molecule substances.

4. Hypoxia

After the anaerobic reaction in the tank, it enters the anoxic tank for denitrification reaction to further remove ammonia nitrogen.

5. Aerobic pool

In the aerobic pool, the remaining organic carbides are digested and removed through biological contact oxidation. The main process is mechanical blast oxygenation and biological contact oxidation treatment technology. The sewage passes through the pond's suspended filler to intercept the suspended matter in the sewage, and remove the suspended matter in the sewage. Colloidal substances are adsorbed on its surface. The organic matter allows microorganisms to multiply rapidly under sufficient oxygen conditions. At the same time, these microorganisms further adsorb suspended colloids and dissolved substances in the sewage, gradually forming a biofilm. The sewage is purified through the adsorption and oxidative flocculation of the biofilm.

6. Sedimentation tank

After the biochemical aerobic reaction, the wastewater enters the sedimentation tank for solid-liquid separation. The sludge sinks to the bottom of the tank and is pumped into the sludge concentration tank through a sludge pump for pressure filtration. The supernatant liquid reaches the standard and is discharged.

Commonly used chemicals for slaughtering wastewater treatment:

Flocculant: Sometimes also called coagulant, it can be used as a means to strengthen solid-liquid separation and is used in primary sedimentation tanks, air flotation machines, tertiary treatment or advanced treatment. Mainly include polyacrylamide and sodium polyacrylate.

Coagulant: Assists the flocculant to work and enhance the coagulation effect. Mainly include aluminum sulfate, alum, green alum, polyaluminum chloride, ferric chloride, polyferric sulfate, and lime.

Defoaming agent: mainly used to eliminate large amounts of foam that occurs during aeration or stirring.

pH adjuster: used to adjust the pH value of acidic wastewater and alkaline wastewater. Mainly include lime, caustic soda, sodium carbonate, sulfuric acid and hydrochloric acid.

Redox agent: used for the treatment of industrial wastewater containing oxidizing or reducing substances.

Disinfectant: used for disinfection treatment after wastewater treatment before discharge or reuse. Mainly include thiazolinone, sodium hypochlorite, and organic sulfur fungicides.

Phosphorus remover: Phosphorus remover can remove turbidity from sewage. The phosphorus content of water treated with phosphorus remover will be reduced below the limit value (removal of inorganic phosphorus).

Polyacrylamide Treatment of Coal Washing Wastewater

Introduction to food wastewater and common treatment methods

Introduction to papermaking wastewater and common treatment methodsCharacteristics of papermaking wastewater:Papermaking wastewater is very harmful, among which black water is the most harmful. The pollutants it contains account for more than 90% of the total pollution emissions from the papermaking

Introduction to printing and dyeing wastewater and common treatment methodsCharacteristics of printing and dyeing wastewater: Textile printing and dyeing wastewater has the characteristics of large water volume, high content of organic pollutants, high alkalinity, and large changes in water quality.