E-mail: admin@saifutd.com Tel: 86-13598853789

E-mail: admin@saifutd.com Tel: 86-13598853789

news

Characteristics of printing and dyeing wastewater: Textile printing and dyeing wastewater has the characteristics of large water volume, high content of organic pollutants, high alkalinity, and large changes in water quality. It is one of the difficult-to-treat industrial wastewaters. The wastewater contains dyes, slurries, auxiliaries, oils, Acid and alkali, fiber impurities, sand substances, inorganic salts, etc.

Basic understanding of printing and dyeing wastewater: It has the characteristics of large volume of wastewater, high temperature, dark color, alkalinity, and high load of organic pollutants. Individual physical, chemical, and biological methods all have their own treatment advantages, but they all have shortcomings, it is difficult to ensure that wastewater treatment meets standards.

Classification of printing and dyeing wastewater

1. Desizing wastewater: small amount of water, high concentration of pollutants, mainly containing slurry and its decomposition products, fiber scraps, acid, starch alkali and enzyme pollutants, with high turbidity; the wastewater is alkaline, with a pH value of 12 about. When using starch slurry, both BOD and COD are high, and the biodegradability is good; when using synthetic slurry, the COD is very high, the BOD is less than 5 mg/L, and the water biodegradability is poor.

2. Cooking wastewater: large amount of water and high concentration of pollutants, mainly containing cellulose, fruit acid, wax, grease, alkali, surfactant, nitrogen-containing compounds, etc. The wastewater is highly alkaline, has a high water temperature, is brown, and has very high COD and BOD, reaching thousands of milligrams per liter. The pollution of chemical fiber cooking wastewater is relatively light.

3. Bleaching wastewater: Large amount of water, light pollution, mainly containing residual bleach, a small amount of acetic acid, oxalic acid, sodium thiosulfate, etc.

4. Mercerizing wastewater: High alkali content, NaOH content is 3%-5%. Most printing and dyeing factories recover NaOH through evaporation and concentration, so mercerizing wastewater is generally rarely discharged. After repeated use in the process, the final discharged wastewater is still strongly alkaline. BOD, COD and SS were all higher.

5. Dyeing wastewater: The water quality is changeable, sometimes containing toxic substances when using various dyes (alkali sulfide, tartar, aniline, copper sulfate, phenol, etc.), alkaline, and the pH sometimes reaches more than 10 (using sulfide and vat dyes) ), containing organic dyes, surfactants, etc. It has high chroma, less SS, higher COD than BOD, and poor biodegradability.

6. Printing wastewater: contains slurry, high BOD and COD.

7. Wastewater from the finishing process: mainly contains fiber scraps, resin, formaldehyde, oil and slurry, with a small amount of water.

8. Alkali reduction wastewater: It is produced by the alkali reduction process of polyester imitation silk. It mainly contains polyester hydrolyzate terephthalic acid, ethylene glycol, etc., of which the terephthalic acid content is as high as 75%. Alkali reduction wastewater not only has a high pH value (generally >12), but also has a high concentration of organic matter. The CODcr in the wastewater discharged from the alkali reduction process can be as high as 90,000 mg/L. High molecular organic matter and some dyes are difficult to biodegrade. This kind of The wastewater is high-concentration organic wastewater that is difficult to degrade.

Printing and dyeing wastewater treatment methods:

1. Adsorption method: The most commonly used physical treatment method is the adsorption method. This method is to mix the powder or particles of porous substances such as activated carbon and clay with wastewater, or to let the wastewater pass through a filter bed composed of its granular materials. A method in which pollutants in wastewater are adsorbed on the surface of porous materials or removed by filtration. The adsorption rate, BOD removal rate and COD removal rate of activated carbon reach 93%, 92% and 63% respectively.

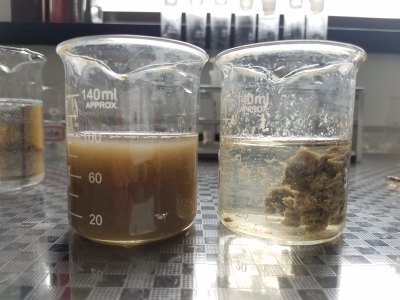

2. Coagulation method: There are mainly coagulation sedimentation method and coagulation flotation method. Most of the coagulants used are aluminum salts or iron salts. Among them, polyaluminum chloride (PAC) has better bridging adsorption performance. good. The main advantages of the coagulation method are simple process flow, convenient operation and management, low equipment investment, small floor space, and high decolorization efficiency for hydrophobic dyes; the disadvantages are high operating costs, large amounts of sludge, difficulty in dehydration, and environmental degradation. Water-based dye treatment is ineffective.

3. Oxidation method: The oxidation method can achieve good decolorization effects on most dyes, but has poor decolorization effects on water-insoluble dyes such as vulcanization, reduction, and coatings. Judging from the operating experience and results at home and abroad, this method has good decolorization effect, but it consumes a lot of power and has certain difficulties in large-scale promotion and application. Oxidation treatment of printing and dyeing wastewater has high decolorization efficiency, but equipment investment and power consumption need to be further reduced.

4. Electrolysis method: Electrolysis has a good treatment effect on printing and dyeing wastewater containing acid dyes, with a decolorization rate of 50%-70%, but it has poor treatment effect on wastewater with dark colors and high CODcr.

5. Biological method: Among the biological treatment methods of printing and dyeing wastewater in my country, surface accelerated aeration and contact oxidation methods account for the majority. In addition, blast aeration activated sludge method, jet aeration activated sludge method, biological turntable, etc. are also used, and biological fluidized bed is still in the experimental application stage. Since the color removal rate of organisms is not high, generally around 50%, when the effluent color requirements are high, physical or chemical treatment is required.

Printing and dyeing wastewater treatment chemicals

Polyacrylamide, polyaluminium chloride: are commonly used flocculants and coagulants in sewage treatment. The two are generally used together to achieve the effect of coagulation, flocculation and sedimentation. It is mostly used to deal with floating matter, impurities, pigments and other problems in printing and dyeing wastewater. It can be used for pre-processing at the front end of the process and in-depth processing at the back end of the process.

Sulfuric acid and sodium hydroxide: are two pH regulators commonly used in printing and dyeing wastewater treatment. They are used to adjust the pH of wastewater to ensure that sewage is treated and discharged within a suitable pH range. Other agents for treating conventional indicators are also used, such as oxidants, ferrous iron (reducing agent), etc.

Introduction to food wastewater and common treatment methods

Introduction to papermaking wastewater and common treatment methods

Introduction to papermaking wastewater and common treatment methodsCharacteristics of papermaking wastewater:Papermaking wastewater is very harmful, among which black water is the most harmful. The pollutants it contains account for more than 90% of the total pollution emissions from the papermaking

Introduction to printing and dyeing wastewater and common treatment methodsCharacteristics of printing and dyeing wastewater: Textile printing and dyeing wastewater has the characteristics of large water volume, high content of organic pollutants, high alkalinity, and large changes in water quality.