E-mail: admin@saifutd.com Tel: 86-13598853789

E-mail: admin@saifutd.com Tel: 86-13598853789

news

Characteristics of papermaking wastewater:

Papermaking wastewater is very harmful, among which black water is the most harmful. The pollutants it contains account for more than 90% of the total pollution emissions from the papermaking industry. Because blackwater is highly alkaline, dark in color, has a strong odor, and has a lot of foam, It consumes a large amount of dissolved oxygen in water, seriously pollutes water sources, and brings harm to the environment and human health. The most serious environmental pollution is the chlorine-containing wastewater produced during the bleaching process, such as chlorine bleaching wastewater, hypochlorite bleaching wastewater, etc. In addition, the bleaching waste liquid contains dioxins, a highly toxic carcinogen, which also poses a serious threat to the ecological environment and human health.

The composition of papermaking wastewater:

Pulp and papermaking wastewater is mainly divided into three types: black liquor, intermediate wastewater and white water.

Black liquor: Cook plant fiber with an alkaline agent containing NaOH or NaOH + sodium sulfate to dissolve lignin. The discharged cooking liquid is "black liquor" (alkali boiling is black liquor, acid boiling is red liquor, most of which use alkali boiling) ). Black liquor contains lignin, polypentose and total alkali, and is a highly concentrated wastewater that is difficult to degrade.

Middle section wastewater: wastewater produced during the washing, screening and bleaching processes of pulp made by alkali boiling. The COD load per ton of pulp is about 310kg. BOD/COD is between 0.20 and 0.35, and its biodegradability is poor. The pollutants are mainly soluble COD such as lignin, cellulose, and organic acids. The most serious pollution is the chlorine-containing wastewater produced by bleaching.

White water: Large amount of water, mainly containing fine fibers, fillers, coatings and dissolved wood components, mainly insoluble COD, poor biodegradability, and the added preservatives are toxic.

Treatment technology of papermaking wastewater:

Black liquor, mid-section wastewater: alkali recovery, acid precipitation method, LB-1 alkali analysis method, membrane separation method, flocculation sedimentation, biofilm method, anaerobic biological treatment, mesh microfiltration, air flotation, advanced oxidation.

White water: filtration, flotation, sedimentation, screening.

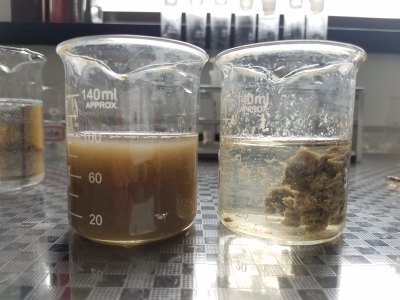

The concentration of SS and COD in waste paper wastewater is relatively high. COD is composed of insoluble COD and soluble COD. Usually insoluble COD accounts for the majority of the total COD. When SS is removed from the wastewater, absolutely no Most of the non-soluble COD is removed at the same time. Therefore, the main problem to be solved in waste paper wastewater treatment is the removal of SS and COD. The main methods are as follows:

(1) Air flotation or sedimentation method. Using flotation or sedimentation methods and adding coagulant, most SS can be removed, while most of the insoluble COD and some soluble COD and BOD5 can be removed.

(2) Combination of physical and biochemical treatment. For large and medium-sized waste paper-making enterprises with low discharge of papermaking wastewater and high COD content in wastewater, it is difficult to achieve the national first-level emission standards through the physicochemical method of single-stage air flotation or sedimentation, because soluble COD and BOD5 mainly Biochemical methods are required to effectively remove it. Generally, physical and chemical plus biochemical treatment methods are used.

(3) Sludge disposal and comprehensive utilization. The loss of slurry is inevitable during the papermaking process. Recycling the waste slurry flowing into the wastewater has two benefits: First, the recycled slurry can be reused in papermaking or sold as raw material for low-grade paper, generating direct economic benefits; secondly, It is to reduce the wastewater treatment load and reduce the consumption of chemicals.

Recycling and utilization of papermaking wastewater:

Since papermaking wastewater consists of three types of wastewater: black liquor, beater wastewater and paper machine wastewater, its recycling is mainly targeted at these three types of wastewater.

Black liquor recycling

(1) Traditional alkali recovery method (combustion method).

The papermaking industry uses a large amount of alkali, and 200-400 kg of caustic soda is required to produce 1 ton of pulp. There are about 35% inorganic substances in the black liquor discharged after cooking, and its main components are free NaOH, Na2S, Na2SO4 and other sodium salts combined with organic matter. The purpose of alkali recovery is to convert these sodium salts into NaOH and Na2S for recycling to reduce costs and reduce pollution to water bodies.

(2) Wet oxidation method.

Wet air oxidation refers to the process in which organic matter in wastewater is oxidized and decomposed under high temperature and high pressure. The degree of oxidation depends on the temperature and pressure used. This method is suitable for caustic soda black liquor.

(3) Wet cracking method.

The wet cracking method for recovering rice straw pulp black liquor is a new technology unique to my country. The black liquor undergoes a wet cracking reaction at about 20 MPa and 360°C for 15 to 30 minutes. The organic matter in the black liquor is converted into gas, tar, carbon powder and organic acid. Sodium silicate is converted into SiO2 precipitation under high CO2 partial pressure. The cracked products are then separated by sedimentation method under normal pressure, and the separated liquid can be causticized to recover alkali.

(4) SCA-Bilero got the law.

The basic principle of this method is similar to the air oxidation method. The black liquor concentrated to 50%-60% is instantly thermally separated in a thermal decomposition furnace under conditions of insufficient oxygen. The decomposition products are Na2CO3, H2S, C, etc.

(5) Comprehensive utilization methods of black liquor.

Recover sulfate turpentine, use black liquor to prepare humic acid ammonia, recover tarot oil, use black liquor to prepare dimethyl vitriol, etc. In addition, lignin can be recycled to produce alcohol and yeast.

Beater wastewater recycling

The wastewater discharged from the pulp through the beater contains the same components as black liquor, but the concentration is lower. Due to the small amount of organic matter (fiber and alkali, etc.) contained, recycling is difficult, but the total solids, suspended solids and BOD5 in the wastewater are still high, and direct discharge still causes serious water pollution, so it needs to be treated. The main treatment methods include coagulation sedimentation method, air flotation method, activated sludge method, stabilization pond method, biological filter method and A/O method, etc.

Paper machine wastewater recycling

The wastewater discharged from the paper machine contains a large amount of fiber. If it is not recycled, it will cause a lot of waste. Therefore, the wastewater from the paper machine must be fully recovered and reused. Part of this water can be used to dilute the paper pulp (such as the white water discharged from the suction machine), and part of it can be sent to the pulping project (the wastewater squeezed out by the water suction tank and the suction machine). The wastewater that cannot be used in the pulping project should be sent to the recycling device for feed Recycle.

Treatment chemicals for papermaking wastewater:

During the papermaking process, organic chemicals used as additives or additives are not completely retained in the paper web and some are lost to the wastewater. This part has a certain impact on drainage water quality, leading to an increase in COD and other indicators. The main sources of adsorbed organic halides are chlorine bleaches, disinfectants and some additives. Raw material preparation, chemical pulping and washing in the papermaking process are all processes that generate wastewater. COD, BOD and AOX (absorbable organic halogens) in the wastewater will greatly affect the water quality.

The selection of papermaking wastewater treatment agents can be achieved by using flocculants. The flocculation and sedimentation method has the advantages of simple process, convenient operation and management, high COD removal rate, and avoidance of secondary pollution. It has low cost, good treatment effect, and good economic and environmental benefits. This is an effective primary treatment method that can be used in paper mills.

Of course, in addition to aluminum sulfate, ferric chloride, ferrous sulfate and polyaluminum chloride are also efficient flocculants. In addition, for the treatment of a large number of small particle wastewater with a relative density close to water, the air flotation method can be used to pressurize and aerate the wastewater before decompression, so that suspended solids are removed as the bubbles rise; advanced oxidation processes such as biological treatment technology , anaerobic biological treatment, aerobic biological treatment, etc. are also very effective treatment methods for paper production wastewater.

Introduction to papermaking wastewater and common treatment methodsCharacteristics of papermaking wastewater:Papermaking wastewater is very harmful, among which black water is the most harmful. The pollutants it contains account for more than 90% of the total pollution emissions from the papermaking

Introduction to printing and dyeing wastewater and common treatment methodsCharacteristics of printing and dyeing wastewater: Textile printing and dyeing wastewater has the characteristics of large water volume, high content of organic pollutants, high alkalinity, and large changes in water quality.