E-mail: admin@saifutd.com Tel: 86-13598853789

E-mail: admin@saifutd.com Tel: 86-13598853789

Products

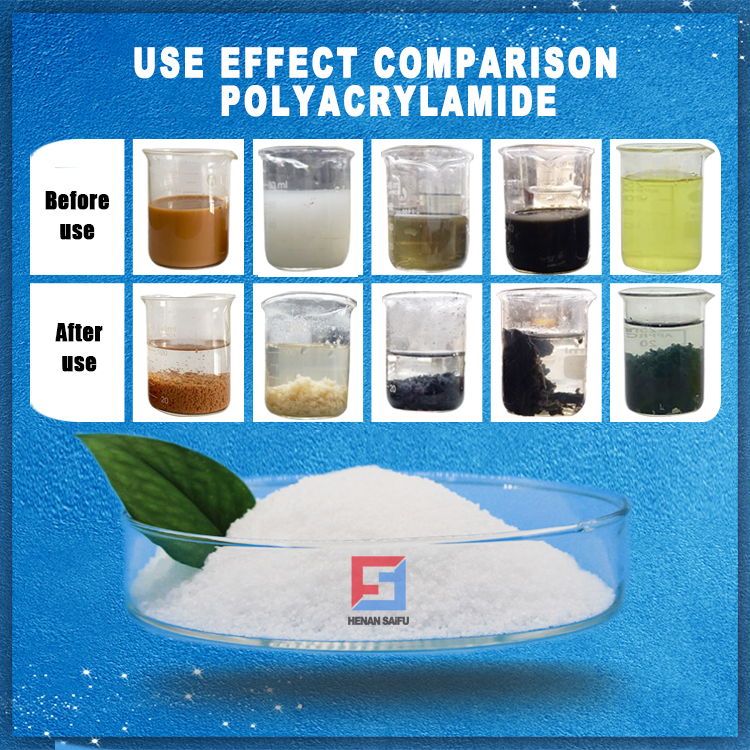

Anionic polyacrylamide (APAM) is a water-soluble polymer, which is mainly used for flocculation and sedimentation and sedimentation clarification treatment of various industrial wastewater, such as steel mill wastewater, electroplating factory wastewater, metallurgical wastewater, coal washing wastewater, etc. Mud dehydration etc. It can also be used for clarification and purification of drinking water. Because its molecular chain contains a certain number of polar groups, it can absorb solid particles suspended in water, bridge or aggregate particles between particles, and form large flocs through charge neutralization, so it can accelerate particles in suspension . Settling has a very obvious effect on accelerating solution clarification and promoting filtration.

Anionic polyacrylamide (APAM) is a water-soluble polymer, which is mainly used for flocculation and sedimentation and sedimentation clarification treatment of various industrial wastewater, such as steel mill wastewater, electroplating factory wastewater, metallurgical wastewater, coal washing wastewater, etc. Mud dehydration etc. It can also be used for clarification and purification of drinking water. Because its molecular chain contains a certain number of polar groups, it can absorb solid particles suspended in water, bridge or aggregate particles between particles, and form large flocs through charge neutralization, so it can accelerate particles in suspension . Settling has a very obvious effect on accelerating solution clarification and promoting filtration.

| Name | Anionic Polyacrylamide | Molecular weight | 6-20 million |

| Appearance | White granule or powder | Solid content | ≥90% |

Functional properties of anionic polyacrylamide

Anionic polyacrylamide, due to its:

1. Clarification and purification;

2. Promote precipitation;

3. Promote filtration;

4. Thickening and other functions.

It can fully meet the requirements of various fields in waste liquid treatment, sludge concentration and dehydration, mineral processing, coal washing, paper making, etc.

Coal washing wastewater treatment plan:

Coal preparation plants generally use the treatment process of "cyclone thickener-filter press (coal slime sedimentation tank)" to treat slime water. Generally, it is a purchased polymer flocculant (polyacrylamide). The contact between the polymer flocculant and the coal slime particles or coal slime colloids neutralizes the electrical properties of the coal slime surface, reduces the surface energy, and causes the coal slime particles to coagulate and precipitate. The molecular weight of polyacrylamide is generally between 1 million, and flocculants with different molecular weights should be selected for the slime water composed of different particle sizes. Polyacrylamide can be divided into three types: anionic polyacrylamide, cationic polyacrylamide and nonionic polyacrylamide. When using polyacrylamide for water treatment, it is necessary to ensure that the species matches the pH of the slime water. Anionic polyacrylamide is suitable for alkaline slime water, and cationic polyacrylamide is suitable for acidic slime water. Anionic and cationic polyacrylamide are mixed, and the slime water flocculation and sedimentation effect is better.

feature:

1. Good water solubility, can be completely dissolved in cold water.

2. Add a small amount of this anionic polyacrylamide product to get a good flocculation effect. Generally only need to add 0.01~10ppm (0.01~10g/m3) to give full play to its effect.

3. Anionic polyacrylamide products and inorganic flocculants (polyferric sulfate, polyaluminum chloride, iron salt, etc.) are used at the same time, which can show a greater effect.

How Polyacrylamide Works

1) Principle of flocculation: When PAM is used for flocculation, it is related to the surface properties of the flocs, especially the momentum, viscosity, turbidity and pH value of the suspension. Momentum at the particle surface is responsible for particle inhibition. PAMs with opposite surface charges can lower the momentum and aggregate.

2) Adsorption and bridging: PAM molecular chains are fixed on the surface of different particles, and polymer bridges are formed between the particles, so that the particles form aggregates and settle.

3) Surface adsorption: various adsorptions of polar group particles on PAM molecules.

4) Reinforcing effect: PAM molecular chains and dispersed phase implicate the dispersed phase through various mechanical, physical and chemical effects to form a network.

Application fields of polyacrylamide

1. Coal washing plants use polyacrylamide for coal slurry sedimentation and concentrated tailings filtration. Please choose anionic polyacrylamide, nonionic polyacrylamide, and low cationic polyacrylamide.

2. Please choose anionic polyacrylamide or nonionic polyacrylamide for wastewater in the paint industry. For the treatment of paint wastewater, the traditional method is to coagulate the mixed wastewater directly. The treatment effect is unsatisfactory, the effluent quality is unstable, and it is difficult to discharge up to the standard.

3. Please choose cationic polyacrylamide for biological waste liquid treatment and sludge treatment in dairy industry.

4. Anionic polyacrylamide, nonionic polyacrylamide, and low cationic polyacrylamide are used to treat electroplating wastewater containing cyanogen oxide.

5. Anionic polyacrylamide, low cationic polyacrylamide, and nonionic polyacrylamide are used for copper mine tailings wastewater treatment.